Update 11/3/14

The system has been running for a couple of years now and there is good news and bad news. The good news, it all works. Happily, the whole proof of concept has been successful. The bad news is that I don’t have enough heat in the winter, and too much in the summer. So, we’re going to do some experimentation in 2014. We’re also going to add PV’s. Finally! So, Phase-2 is here.

Where the system is today vs. where we started:

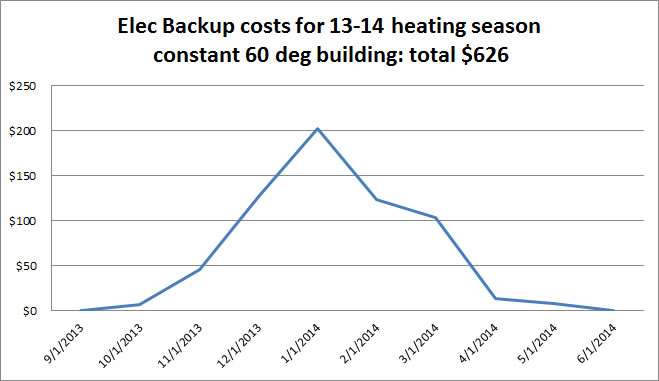

By looking at all the data collected since the system was started, maybe 40% of the heating requirements of the building are met by the current solar thermal system. In the 2013/14 heating season, I kept the building’s heat constant at 60 degrees as a baseline. The electric backup in the storage tank created the additional heat not provided by the solar panels. As usual, we had a crappy, cloudy Jan/Feb so the electric usage was high. Total cost of the backup heat for the year was around $626 (3,600kW’s).

The control system to keep the building at a minimum temperature was about as simple as I could make it. I have 2 thermostats in the building, one in the office area and one in the shop, located in the perfect center of the building. Both thermostats are in parallel with a solid state relay to control the 4.5kW heating element in our 120 gallon storage tank. There is also a pipe mounted hydrostat located on the output side of the panels so that if the thermostats are calling for heat but the solar system turns on, it will disable the electric backup while the solar system is producing. As long as the solar system is not making heat, and at least one of the thermostats is on, the solid state relay will energize, turning on the backup element. The tank then warms and when it reaches an upper tank temperature of 80 deg., the slab valve will open and the circulator will start circulating. The electric backup will generate around 15 kBTU when it all stabilizes.

In 2013 I added a heat exchanger for the hot tub. The tub has been fully heated and has become a heat dump in the summer. It’s starting to look like we have a winter/summer heat load imbalance problem.

I finally added solar hot water to the system. We purchased a dual coil insulated 80 gallon water tank for our DHW needs. Along with adding the new tank, we added a new oil furnace to replace the 30+ year old monster that was here. Water heating is now an indirect heated system (zone off the boiler) as well as solar at the same time. The lower coil in the tank is connected to the solar, so even if we don’t have enough solar to heat the entire tank, we will at least pre-heat the water, using less oil. The great thing about this system is that we never run out of hot water and the temp is constant.

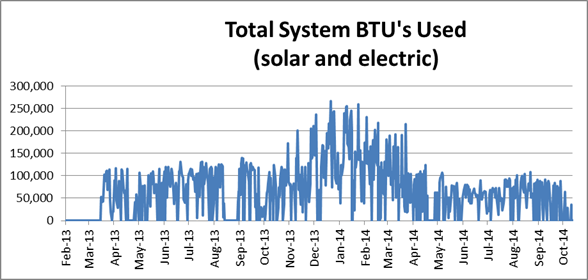

The seasonal load imbalance is quite visible when you look at the total output from the system over a year. The chart below shows that 30 year old system still makes around 100 kBTU on average, most of which gets dumped in the summer months. Then comes January-February and the demand is now 2.5 times the system’s output. (Note, due to a crappy flow meter, the data has some holes, but you get the idea).

There has to be a better way. I can’t stand spending money in the summer to keep the pumps running both in the panels and in the tub to dump the heat I’m making. Should I cover the panels? I don’t like roofs these days so that option is out.

Obviously it was time to take a step back, look at where I started, where I am, and where I’d like to be. Research time again. Following along the same 1980’s technology path I started on, the next thought was to change the tilt angle of my panels to 60 degrees-ish. Ok, that makes sense. Maybe I still don’t have to dump as much, or hopefully at all. But, that really doesn’t fill that 2.5x heat requirement I have in the winter. Do I just add more panels? The next thought is I hang a few recycled panels I have vertically along the wall of the barn, under the overhang where they are shadowed in the summer. Cool, that might just work. So, I make drawings, play around with some calculations and tinker with the idea for a while. I soon come to the realization that this is beyond my capabilities to actually implement this by myself (and the roof thing). It’s time to take that next step and look for someone to actually take this concept and mount it on my building and make it work. The more I started looking for installers, the more I thought that maybe this is the time to make a huge leap, develop a plan with a budget, and do this all for real.

The fall of 2014 comes along and it’s time for me to take the next leap in the project. It started, funny enough, with a simple phrase that popped into my head (and stuck there) that I have now plastered on my walls, screensavers and even a coffee cup! It was time to change that boring title of Granville Solar Barn Project…. Welcome to:

Phase-2.

As of the 3rd week of November 2014, the project has started. I set a budget, went out for quotes and have just committed to 7.2kW of photovoltaic panels on the west side of the barn’s roof, and 224 ft2 of new flat plate collectors and drainback system for the eastern side of the roof. That will cover about 90% of the roof surface! This is what we built it for, I’m just psyched. I will be thrilled to announce that my business (me and the cat) will be 100% solar powered/solar heated in the spring of 2015. I’ve been burning fuel my entire life, time to minimize that.

Mass Storage Tests

For me, one of the most exciting things about this point in the project, especially as an engineer, is finally learning what the mass storage concept will do. The solar thermal upgrade is being designed to support the mass storage concept. I’ve worked with electronics my entire life. I deal with laser systems where our response times and control parameters are in uSec’s and mSec’s. When dealing with solar heated thermal mass, I’m now dealing with response times of parts of a day! This is a whole new world to me and it’s making me think. For details, Phase-1 describes the thermal mass concept. To me, being an electronics-kinda-guy, the whole thermal mass system is a like a big capacitor. We charge it, and then discharge it. There will be lots to learn like charge and discharge rates, how much energy we can actually store in 71 tons of sand in an insulated box, how long that heat can be stored. In electronics, we use capacitance to filter voltages that may swing up or down, storing energy when there is excess, releasing that energy when required. Using the thermal mass as my capacitor, I’m curious if it will react the way an electrical circuit might. My whole purpose of mass storage is to test the validity and cost effectiveness of getting through “the dark months”, the dead of winter in New England, without burning anything, then hopefully spreading that info whether it ends up working or not.

Solar Electric

We are installing 7.2kW in 24 panels of 300 W each. The system is being installed by Northeast Solar with a scheduled startup sometime next spring. I’m amazed at how long the process takes to just get ready to install. Our electric usage is too high. We are somewhere around 14,000kW annually. The system is projected to make around 8,000kW annually. With a little better conservation, along with the fact that we will no longer be using as much electric backup for the shop, we hope to see a 75% reduction in our purchased electricity. Without the solar thermal changes, we'd probably only cover 50%.

Solar Thermal

It took a bit of searching to find someone to look at my proposed upgrade, but finally I contacted Spartan Solar out of Greenfield, MA. Spartan was a bit hesitant about a few things; I’m a ways away, my concept and system was 80’s technology and I was going about the seasonal imbalance issue the wrong way. Somewhere during our phone conversation, I mentioned the fact that I had 71 tons of thermal mass and 900 feet of imbedded PEX buried under my building. There was shock, loud noises and laughter from the other end of the phone. I think I triggered something. What I heard was someone who actually understood what it was I was trying to do and equally excited to learn about thermal mass relative to solar space heating. We met and came up with a plan. The new system will consist of 224 ft2 of new panels:

(4) 4x8 Heliodyne GOBI 408 panels

(4) 4x6 Heliodyne GOBI 406 panels

In talking to a couple of professionals while investigating all this, I learned about the need for steamback or drainback protection. Once Spartan and I discussed it, and I went off reading, I became a huge fan of drainback designs. I design control systems for a living, there is nothing better than a (mostly) fool proof system. Overheated panels? Drain the system. Too cold? Drain the system. Power loss? System drains itself. Here was the answer to my seasonal imbalance issue. I can now oversize a system and not have to worry about where to dump the heat. When I don’t need the panels, they drain. I just love simplicity.

The new system will also have an additional 120 gallon insulated storage tank and heat exchanger. The extra storage will help buffer things. It’s like adding another capacitor, some additional smoothing. It also means the system will need to cycle less in the summer, since most of our daily load hopefully will be stored within the 240 total gallons. The additional new tank also adds more reliability to the entire system. The existing old Sepco tank has seen better days, I’m sure it will last another 30 years, but what if the heat exchanger fails? What if’s. I like to cover those whenever possible, the best I can. Once this system becomes active, I will be dependent on it, so minimizing potential down time is important.

Controls

Back in the initial description of this project, I mentioned adding intelligence to the control system. Up until now, I just didn’t have enough of a heat source to do much except put every bit of it into the floor when available. The control system was simple: got heat, turn on the slab valve and pump away until there is no more heat. The thermostats were only used to turn on the electric backup should the building go below the 60 degree set point. I did attempt a PC based control system for a while, but after a power failure while we were away on a warm island, I changed that. We came home to a 38 degree building. The cat was pissed. So I switched over to the simple hardwired system I have now.

The new control design still has the PC in place, but simply doing the same data acquisition functions it does now. I have to go with something I’ve worked with from the start, the PLC (Programmable Logic Controller). Power goes off, it goes off. Power comes back on, it comes back on. The cat will be pleased. By adding some industrial controls to the system, I gain reliability as I step away from that simple hardwired approach. I now will have much more heat to deal with and will have to find ways of distributing that heat where it is needed based on the time of year, time of day, temperature outside. I’m finding that it looks like the best way to maintain a constant heat is to anticipate when that heat will need to be in the slab and get it there before it drops too much in temperature. This is where the additional water storage and eventually the thermal mass storage will help. I just need to figure out how best to keep the slab at a constant temperature with an inconsistent heat source. Sure looks simple when you write it.

The PLC will consist of 4 thermocouples for panel in/out and tank in/out temps, inputs for flow meters and thermostats and relay outputs for valve, pump and backup heat. The basic control concept is similar to a simple zone controller in a heating system, perhaps one with a priority zone. My priority zone in the winter is the slab but other times of the year, it is the house. The system will be smart enough to know that. How the heat will be distributed, whether all at once (parallel), or one device at a time (timeshare), will need to be played with. Oh boy, the fun part. This is why I must have a programmable approach to my system. I can’t purchase anything off the shelf to do what I need it to do, partially because I don’t know what I need it to do. Yet.

Aside from the control logic, the PLC will also keep track of BTU’s collected and BTU’s used, updated each minute. The PC data logging software will have access to both the current output and the total daily output and log to the website as it currently does.

It’s about to be Thanksgiving. We now sit back and wait for the permitting process and the like. Can’t wait to exploit the sun.